Your cart is currently empty!

How to Make BHO Step by Step with TheCapn

TheCapn makes BHO. BHO = butane hash oil, and also known as wax, shatter, honeycomb, honey oil, and whatever we stoners decide to call it at the time. My goal with this article is to provide the most complete instructions to make shatter. I’ve seen many stoners attempt to make videos on how to do it, but I’ve never seen a complete, step by step method online.

Specifically, I’ll show you how to make, what is most widely known as, “shatter”. There are many variations, and I can’t possibly cover them all. If you want to make something different, I may be able to help, however this article is focused on BHO, or shatter, so we will keep the subject there.

This post has been a long time in the making. I’ve been cooking up a batch about once a week, for the last year, and I just now feel as if I’m qualified to teach someone else how to do it. I am still learning more every day, and I have been “tweaking” the technique over the last year. I’ve learned many many lessons. There is SO MUCH that can go wrong when you make BHO. It is somewhat of an art, but if you follow my directions exactly, your product should turn out very similar.

I’m not the god of BHO. There are many ways to make it and many many more opinions. I’ve been hesitant to write this article, because articles on Shatter, bring the stoner squids out of the woodwork. I’m writing this article because I have taught many people how to make it, and I’d rather just send them to the instructions. This is the way I do it. I spent a lot of time and money making several batches before I was able to consistently make good shatter. If you follow these instructions, you should be able to make great shatter the first time. And when I say GREAT, I’m talking full melt, mind bending, clean, great tasting shatter. You’re welcome to try it this way or any other way. If you post any “hater” comments, I’ll delete them.

A nice BHO “Patty” as we call it, just after flipping from one side to the other. My Blue Dream Pheno makes the most stable (hard) shatter I’ve ever seen.

First, here are some bullet points you need to know first, about what we can expect.

Equipment: If you want to blast a couple hundred grams at a time, you’ll need a nice tube, a stand to hold it in, a vacuum, a chamber to purge in, heating pan, etc. Plan on spending about $500 in equipment to get started. If you just want to blast a couple zips at a time, your budget will be about $350. Either way, you still need a good vac pump and chamber. If you’re blasting pounds at a time, you’ll still get some benefit from this article, but you’ll probably want to reclaim your butane, and you should look at more advanced equipment. I blast about 200grams at a time, which is about how much yield in frosty trim I get after trimming a one pound chonger. For this relatively small amount, it’s not worth the investment to buy more advanced equipment to save $30 worth of butane.

Yield: from frosty trim, you should be able to get at LEAST 10% yield. Meaning… if you start with 100grams of product, you should get at least 10grams of shatter. From bud, I have got up to 22-23% yield, but normally the yield on bud is around 16-20% (depending on the quality). With some less frosty strains, yields will be around 12-15%.

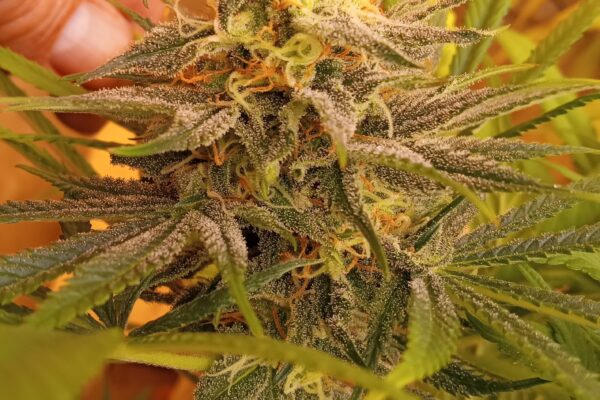

Material: If material is bad, end product will be bad. Plain and simple. You can’t take brick weed and expect it to make good shatter. However, you CAN get great shatter from simple frosty trim (if it is dried and cured properly). I blast every bit of my outdoor grow, and it looks like this. The frostier the material, the more yield you will get.

A beautiful BHO burger made from outdoor grown, OG Kush.

Safety: What you’ve heard is true. There is a LOT that can go wrong, with the worst thing… igniting the butane fumes. Let’s say you’re blasting on your back porch and it starts to get dark. You flip on the light switch. If there is any kind of spark, BOOM! You’re dead and your house is wrecked. When I blast, I literally tape down the light switches so I (or someone else) can’t accidentally turn on the light. Wear safety goggles. Butane WILL spatter out at some point, especially when you are still learning your equipment and finding the correct adapter from your butane can to the tube.

BLAST AT YOUR OWN RISK.

First, we will outline the equipment you need:

A tube to pack your material in, which will hold the material in place so you can run butane thru it. I use the 250g tube from “Extraction Experts”. I only put 180-200 grams in at a time. 250 is too much and you will lose yield. Extraction Experts has many tubes to choose from. Some smaller, some bigger. For the average home grower harvesting a pound or two at a time, I would suggest this tube. If you’re a stoner who wants to blast a half you scored, you can usually get a small tube from your local head shop. I do not recommend getting tubes that use hose clamps and rubber corks to hold the material in. The rubber stopper can pop out, ruining your shatter and getting butane soaked material everywhere.

A vacuum chamber and an electric skillet. I use the “Vac-it pro” 10 inch vac chamber, and a plain electric skillet. Some skillets will hold a consistent temperature, some not. You’ll have to experiment with what you have and make sure it will hold temp within a few degrees. I use a round silicone “silpat” in the bottom of my chamber. This insulates the oil slightly so it warms more evenly, and doesn’t get too hot on the bottom.

A infrared temperature gun: These can be had at your local hardware store for $20-$40. It is absolutely necessary to get one if you want to make quality shatter.

Vacuum Pump: I use a 3cfm, single stage vac pump. I use the one shown is this picture. It’s cheap, ~$50 and I’ve done at least 50 runs with it. For ~one oz shatter patties, and the standard size 3 gallon vac chamber, this is all you need.

A double broiler set up:

I’ve used a dozen different setups but this one works the best. It is a white corning ware oven safe round dish. Then put that inside a regular stove top pan. A round dish works the best because it transfers to the round vac chamber easier. The big pan should have warm water in it. NOT HOT. If you attempt to blast without water in the big pan, the dish could freeze to the surface.

A double broiler set up, and letting the butane out of the tube. Be careful not to let it out too fast and splash.

PTFE: The days of blasting into pyrex and scraping are over. Now we blast straight into PTFE. You can score some PTFE on ebay. After vac, the shatter will peel right off the PTFE. No scraping, no loss of yield.

Blasted right into the PTFE.

Preparing your material:

If you’re going to blast bud: whether it be lower airy buds, or premium tops, you’ll want to dry it and cure it the same way you would if you were making bud to smoke. A day or two before blasting, I’ll take my buds and chop them up with scissors so no bud is bigger than a marble (you can also do this while you’re trimming). Then I let the material dry a little further, to about 50% humidity, before blasting. We don’t want any moisture in the buds, but we don’t want them so crispy that they turn to dust when you handle them. If you attempt to blast before your material is fully dry, your shatter may have a green tint to it.

Speaking of handling your material, do it as LITTLE as possible. Every time you handle it, move it, weigh it, you are losing trichomes. I always cringe when I see people walking around squeezing buds in their gardens.

If you’re going to blast trim: Then you’ll need to think ahead while you’re trimming. Throw fan leaves in the garbage, and cut all the frosty trim into a bin. You’ll have some small fan leaves with a little frost on them. It’s up to you if you want to throw these away or blast them. The more “non-frosty” leaves you put in the tube, the lesser quality and lesser yield you will get. I am fairly generous, and if a leaf is at least 1/2 way covered, I blast it. Here is a typical handful of trim that is ready for blasting. You can see how to trim in another article, “how to harvest, trim, and dry”.

And the bins I use to trim in, shown below. IMPORTANT! After you are done trimming, you will have a bin full of wet trim. This trim must be spread THINLY in bins like this, and allowed to dry. I let it dry for about 5 days, turning it over with my hands once a day. I do not suggest moving the trim into brown paper bags. Again, you are losing trichomes, every time you handle it and put it into a different container. Use the same bins over and over. Eventually, you will have plenty of kief in the bin to scrape up and sprinkle on your joints. Only after it is dry, then you can pile it up as you see here in this picture. At this time I like to put a lid on it, and burp it every day for a week, then it is ready to blast.

Packing your tube: Before packing make sure you now which end is which. Most tubes come with a fine screen on the output. I’ve found that using a coffee filter, in addition to the fine screen, produces a cleaner, clearer product.

Attach the bottom to your tube and start packing from the top. Put in about 3 handfuls, then pack lightly with a piece of PVC pipe, wooden rod, or similar. The material should be packed in so there is no air space around it, but not too tight. Packing it too tight will decrease yield %. This is part of the ART of blasting. You’ll have to experiment to get the “feel” for it, as for what works best for your tube. Attach the top of your tube and you’re almost ready to blast. The important thing here is that all fittings, hose clamps, rubber stoppers, etc, are secure! Pressure will build up inside the tube, and you don’t want leaks or blow outs.

Preparing everything to blast: Before you get ready to start putting in butane, let’s make sure we have everything we need.

1. Tube packed and sealed2. PTFE in our corningware dish, secured with clips, sitting inside our double broiler set up, with WARM water. NOT HOT. Hot water will COOK your shatter, turn it dark and burn off potency and flavor.

3. Approximately one 300ml can of butane for each ounce of material you are blasting.

4. Nothing electric is turned on in the blasting area (not fans, no nothing). Light switches taped down. I’m assuming everyone knows you blast OUTSIDE, not indoors. 😉

5. Safety goggles

6. Dry, clean towel

Blast off! I’m going to tell you how I blast, using my 250 tube. You will probably have a different tube, but you can use the same technique I use here. I blast about 7 zips at a time, so I use 7 cans for each run.

1. Check the tip of your butane can and put it into the top of your tube. It should fit tightly. Butane cans come with a variety of tips that you can exchange to find the best one that works with your tube. With both top and bottom valves wide open, start putting in butane at the top. When your can runs out, close the top valve, remove the can, put on a new can, open the top valve. You don’t want tane squirting out the top of the tube. Work quickly. We want to flood the material as quickly as possible. Keep putting in butane at the top and soon it will start coming out the bottom. When it does, close the bottom valve slightly so it doesn’t spatter everywhere. Let a good amount of butane come out (about a full can), then close the bottom valve. Put in one more full can, if possible. If there is too much pressure, that’s ok. Get in as much as you can, as quickly as you can. I always get in 4 cans in my 250 tube (initially).

2. After the tube is full of butane, take the tube out of the stand, and flip it upside down. This will help get the butane to the top of the tube and make sure all the material is soaked. If the tube has frost on it, or is sweating, you may want to wipe it down. DO NOT get water droplets into your oil. Let the tane flow to the top of the tube for about 3-5 minutes. Soaking longer doesn’t provide a higher yield, and decreases the clarity of your shatter. We are simply trying to flood all of the material with tane at this point.

3. Put the tube back in the stand and open the bottom valve SLIGHTLY. Butane will come out. Let it keep coming out until only air is coming out. Close the valve, wait one minute for more butane to flow down, and open the valve again, letting tane out until it stops again. Now, close the bottom valve and put in a total of two more cans. You may need to let a little pressure out the top or bottom of the tube to get in two more cans. Now, repeat step 2.

4. Again, put the tube back in the stand and open the bottom valve SLIGHTLY. Butane will come out. Let it keep coming out until only air is coming out. Now, use one more can to flush everything out and get the last of it. Keep the bottom valve open slightly until only air is coming out. Close the valve, wait one minute for more butane to flow down, and open the valve again, letting tane out until it stops again. Do this a couple more times until you feel like all the tane is out. Don’t worry about every last drop. The last can that comes out, has VERY LITTLE product in it anyway.

5. Pull your double broiler rig out from under the blasting tube. This will prevent any water droplets from falling into our oil. At any time during the process, if you see water droplets on the tube, you can close the bottom valve, take the tube out and wipe it down, quickly.

Boiling off the butane: You’ll notice the butane / oil mix is boiling. That’s because butane boils at room temperature. If you put your hand above the butane, you’ll feel the cold coming off it. The water in your double broiler will be cool by now. You can pour it out and use some warm water, but no warmer than bath water. Too hot, and you will cook off the flavorful terpenes. You will see some material in your tane that looks like a sea sponge. It is frozen moisture that was pulled out of your plant material. You can scoop it out with a fork, or leave it. If you leave it, you might risk trapping some moisture into the shatter, and it will pop and crackle on a hot nail. Most of the moisture will evaporate out in the vac / Purge process anyway. I rarely pull it out, unless it is excessive.

Keep watching it. The tane will slowly evaporate off. You will know when it’s ready to go into the vac when it looks like this. Here is where it is critical, NOT to use hot water. You can instantly ruin your oil. When it is almost done, I only use room temperature water. For the record, we are going into the house and getting warm water, and taking it outside. We are NOT using any kind of electric warming devices in the butane area. Am I clear enough on this?

DO NOT STIR. Do not pop bubbles, do not swirl your oil around. Don’t be a stoner. Move it as little as possible. Any stirring and your shatter will not look clear at the end, and it will be more difficult to purge all the butane out of the oil

Now, we transfer our PTFE to our vac. Carefully! If you lift of the PTFE out of your container, and the product is runny and about to spill out, then it is too thin. You need to wait longer. The oil should be the consistency of maple syrup. There is no penalty for letting it sit a few extra minutes. The vac chamber should be in the skillet, which is filled with water. It is best to space the bottom of the chamber off the skillet, to heat the chamber more evenly. By doing this, you are creating more of an OVEN. Heat your water to 89-91. Put the lid on your chamber so it starts to warm up like an oven inside. Watch the temp closely. Start low and turn the dial up a hair at a time, until you reach the right temp. DO NOT walk away from your skillet until you are 100% sure the temp will not go over 92.

Pulling the first vacuum. Lots can go wrong here, so pay attention. Your chamber should have a valve between the chamber and the vac. And another valve to let air INTO the chamber. You will use the air valve to control the pressure in the vac. Use the pump valve to hold the pressure in the vac when the pump is off.

CAUTION, if the vac is under pressure and you turn off the pump with the pump valve open, your chamber will suck air from the pump line, and could pull in lubrication from the pump and completely ruin your shatter.

With the lid on, turn on the pump and watch the oil. It will start to puff up like a big muffin. The goal is to get the muffin as big as possible, without it touching the side of the chamber. If it touches the sides, you won’t be able to get it off.

By making a big muffin, we are expanding the oil and allowing air to get to most of it, thereby evaporating any butane left in the oil. Watch it closely and use your air valve to control your muff. It may expand rapidly, so be prepared. Keep the vac on for about 15 minutes, or until the muffin drops. The better quality oil you have, and the more vac you have, the longer the muffin will stay puffed up. Usually, the muffin will stop expanding after about 15 minutes and then you can fully close the air valve and take it to full vac. A more expensive pump doesn’t achieve a higher vac, but it gets there faster. Again, I’m happy with a cheap, one stage, 3cfm pump.

After an hour, your muffin will deflate and start to look like this:

And a few hours later, it will be ready for first flip:

The first flip: The first flip is the most difficult. After this, you’re home free! Slowly let the air in to the chamber to equalize the pressure. Then pull the PTFE out. Fold the outer edges of the PTFE on to the shatter (the pull it back again) in order to get the small amounts of shatter on the outer edges off the PTFE. Do this all the way around so you have a piece that will fit inside your chamber.

Now lay it on top of a piece of parchment paper, and peel it off. The first time you do this, you may have some trouble. You can “cheat” by putting it in the refrigerator for 5 minutes first.

It should come right off, wasting very little, if any:

Now, put it back in the chamber and vac again, at ~90 degrees still. Take it to a full vac. Run the vac for about 5 minutes every couple hours, or whatever it takes to keep a full vac. Flip it every 4-5 hours for 24-48 hours. Each time you flip it and vac it, you are exposing more oil to air, getting out all the butane.

If you find that you cannot get any more “action” on the oil when you vac it (after a few flips) then you can take the temperature up to about 95. This will make the shatter a little more gooey and you will then get more bubbles. I don’t suggest running any higher than 95.

After a vac, the patty will look like this:

Now, leave it in the chamber, and turn the heat up to 95 for about 10 minutes, then take it out. Turning up the heat just for 5-10 minutes at the end will make it look “pretty”.

It’s done! That’s a beautiful burger we just made.

*Don’t heat too much at the end or you will COOK the flavor and potency out of it.

*It’s not necessary to freeze your butane, but it is helpful to freeze your tube first. Butane stays in liquid form better if you can keep it cold.

*Results will vary greatly depending on your technique, your strain, how frosty it is, how you cured the material, and too many other variables to list.

And some Shatter porn:

A nice golden patty, right after flip.

Air bubbles are air bubbles, not butane bubbles.

That’s a thick one.

Wanna make “honey comb”? That’s easy. Follow the same procedure but turn the heat up to 140 at the end, until it looks like this.

The greenish tint to this shatter is from running it when it wasn’t fully dry.

Questions and comments, related to this article, are welcome below.

Comments

32 responses to “How to Make BHO Step by Step with TheCapn”

-

I do it a little different. I pack myh tube. I then close it up attached the vacuum hose to the bottom let the vacuum run till complet vacumm is drawn. I put my butane in the top open the valve and shoot the tane to it till it is pressurized. Close the top valve. Flip it end for end a few time. Let it rest for 5 to 10 min. Then slowly open bottom valve let it drain into the PTFT shoot one more can though while both valves are open.Takes about 4 cans. My column is 24″. From that point everything is the same as you. Always comes out nice. I ordered all my column parts off of ebay from china, I have about $60 in the set up.

-

I always forget how great TheCapn articles are (There’s only a gazillion in my bookmarks from forums all over the place). Read this months ago and just came back to it and now I’m off to do some shopping. 🙂

-

Great article!!! I don’t have the same setup so I use a glass extraction tube that holds about 25-35 grams and followed these directions and it came out great. Still couldn’t get the “shatter” but that is prob my material. Dabs great with full flavor and medicates very well.

-

Great article thanks. One question though. if the water temp is 90 degree f. What kind of temp are you looking for in the oil in the chamber?

-

Is it safe to vac purge inside or should that part be done outdoors as well? Thanks

-

Wanted to say thanks for the spot on instructions! I followed these instructions and got perfect results. Thanks again.

-

Is there any way to separate adhesive from oil?

-

New to this n am going to try very soon. So for shatter while purging its best to keep it at 90 degrees??… And after blasting what should the temperature be?

-

Great walkthrough. Have made extracts for 5 yrs and wish i woulda found this post 5 yrs sooner. Every1 thinks 100 deg. But i 2 have found 80-90 makes nice hard stable shatter. This is easy simple not to over the top any1 starting should read this. Keep dabing safely guys!

-

I’ve got a question…

I use a 90g CCE (for 10 months now) and am realizing that I’m using way too little tane and packing my tube with as close to 90g as I can. I’m sure this is affecting my yeilds and I am intrigued by the way you run tane through your column. My question is regarding pressure, when you are running cans directly through your tube, aren’t you loosing the vaccum? I want to get more tane through my material but also want it to soak then spray. By having both valves open, won’t the system lose its vaccum? Any help or clarification would be kindly appreciated!!! -

Capn, I have been using the method described in this post for a few months now and have been getting incredible results until now and I am wondering if you have an idea of what went wrong. I have been blasting a mixture of og kush and cheese and it has always turned out exactly the same until this run, a beautiful yellow and very stable. For starters, this run did not want to let the butane in yet it was not over packed. After finally getting through the extraction, the patty did not get nearly as big of puffing effect, and stopped showing any reaction after only a few hours. Yet, it is still very gooey and unstable. I am thinking of just making it into edibles, but I was hoping you might have an idea of what went wrong. Thanks for your help.

-

Hey what type of vacuum do you guys use?,and recommend?

I have a Robinair 2 stage 3cfm -

Dude Fuck ya! Lol followed your recipe with completely different equipment and running straight kief but came out bomb.com shatter bro thank you for this LOL

-

And also how many times is ok to reuse same piece of ptfe? If at all and in the 8th picture on this post it looks like your ptfe is in direct contact with water is that so? or is the PTFE in direct contact with the bowl With water outside that bowl…ps. notable note Blast a lot wen using ptfe…I did a small test batch with a half ounce of kief and it was so paper thin on the PTFE after first Purge I could not get it off had to scrape it off and that just results in tiny pieces of it flying everywhere

-

So when you said it should be 92 degrees you mean the water In the double boiler right?

-

I swear by this recipe! Great job Cap’n!!!! Question about honeycomb. You say turn up heat to 140 at the end..is that 140 for the whole time in chamber?

-

Can someone help me out with the PTFE? What thickness? Where to get? I have all kinds of shit showing up at my house and none of it looks like this. HELP!

-

Amazon has PTFE…I personally HATE it. Too hard to do your flips

-

I can’t seem to find the extractor tube.

-

Just tried this and I just made the most amazing stuff better than I’ve been able to find lol thank you so much for a very detailed and well written article

-

i took your advice about a year ago, i was dealing with desperateness the time.I T\took your advice to the tee. then i bought a oven and since then it has been to notch shatter. i have only been at it a little over a year and would put it up against any out their. but now n Washington state u have to get certified and $out of this world. but tks for the tip

-

Very informative,easy to understand,my compliments

-

why do you use a closed loop tube instead of an open blast since you don’t evacuate the tube before blasting I just purchased the 140 set up from best value vac’s and tried sucking the air from the tube before I blasted but the tube would only take about 3/4 of a can so didn’t wash much I believe I’m going to give your method a shot but was wondering about the tube thanks caotbob

-

did everything as explained but came out dark, clear but dark, would this be the product or me doing something wrong used nice nugs slightly ground and thank you so much for your instructional site without question best

-

What is causing my product to stay runny?

-

Hey, I became s member just to say thanks on this post. Thank you for taking a professional approach and making a detailed guide. Thanks for your time!!! I just ran my first batch Using your method, and I have surpassed expectation. This works! Beautiful golden chips!! I’ had to go Pyrex though. I will be finding PTFE… thanks again

-

Excellent walk thru, for the beginner. The only thing that stroked me the wrong way was they cutting up of the organics/material. I wouldn’t do that myself, ever. Its setting up for some potentially newbie poop-soup. Breaking (or cutting) up plant matter prior to extraction gives salts, lipids, waxes, chlorophyll, ect. all an express route out of material and into the solvent; typically leaving you with a darker and hazy end product that needs further processing (winterization) to remedy. (Could be a contributing factor in why that one slab had the green tint to it.) Altho water is a polar solvent and will more readily pull chlorophyll than alchohol I haven’t had issues with the green tint when blasting fresh -off the plant- flash frozen materials. I would think it would have just about as much readily available H2O than material that retained a bit of moisture.

Anyway, just my 2 dabs. Take it for what it is. Thank you for spreading some knowledge and helping the beginner get up an running. -

Which is the easiest of them all for a first timer so I don’t screw it up and is the bud left no good after words

-

I can not find this ptfe only paper

-

Question would parchment paper work in replacement of ptfe

-

Excellent. I really learnt a lot here. Tnx.

-

What do u mean using a round corningware dish is easier to transfer to the vac? Also do i use the Slick brand ptfe sheet or paper?

Recent Posts

First time grower needs help!!!

I have been watching the DGC for quite a while now, not a patreon yet but very soon! I…

Dude Grows Show 1631

What’s Growing On DGC? The Dude and Scotty are Hanging Out Talking Cannabis News, Culture and Growing. https://open.spotify.com/episode/0yS6jok54qSAap0lR9hl6P?si=ec4a2078a2724dab THIS…

Wildberry Cake

Wildberry Cake got sliced

Thank You Grambo!!

You guys gave me this idea. Well more or less Grambo. There was an episode you guys were talking…

Tangie Ripper

Chopped at day 63, Tangie Ripper from Irie Genetics. This was my first run of this strain and I…

Leave a Reply

You must be logged in to post a comment.